Chemical Engineering contributes to Virginia Tech COVID-19 research response efforts

Virginia Tech has a large ongoing effort to provide solutions to many issues related to COVID-19. Researchers in the chemical engineering department are directly involved.

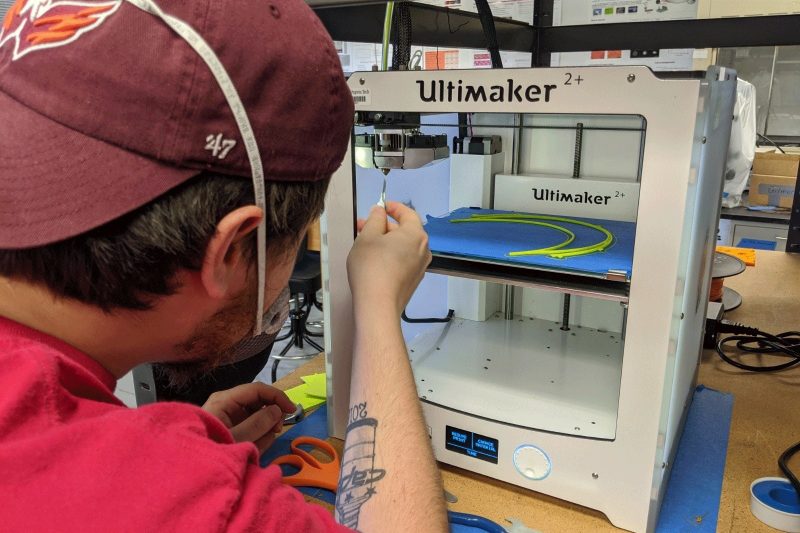

Michael Bortner, assistant professor of chemical engineering at Virginia Tech, and his research group, the Polymer and Composite Materials Laboratory (PCML), have been working to address medical supply shortages. The team is working to help design, qualify and manufacture personal protective equipment (PPE) and testing supplies. Bortner’s group has been contributing to the prototype design and (current) production of 3-D printed face shield frames. The frames are provided to local medical providers and first responders, along with laser cut clear plastic shields and elastic bands to secure the shield to the users. Assembly is generally performed by the user, and has been accepted for use by the Carilion Health System local providers.

The PCML is also actively involved in durability testing and quality control protocol development for 3D printed nasopharyngeal swabs. These swabs are used for collecting samples for COVID-19 testing and are considered to be in extremely short supply. In order to transition to full scale production, the 3D printed swabs must pass a series of mechanical tests to ensure that the materials and process have resulted in a swab that is safe for use on patients.

In addition to being a deadly disease, a key feature leading to the coronavirus pandemic is the ease of transmission between individuals. One mechanism of transmission is via inanimate objects: an infected person transmits the virus to the inanimate object and the next person touches the object before the virus is inactivated.

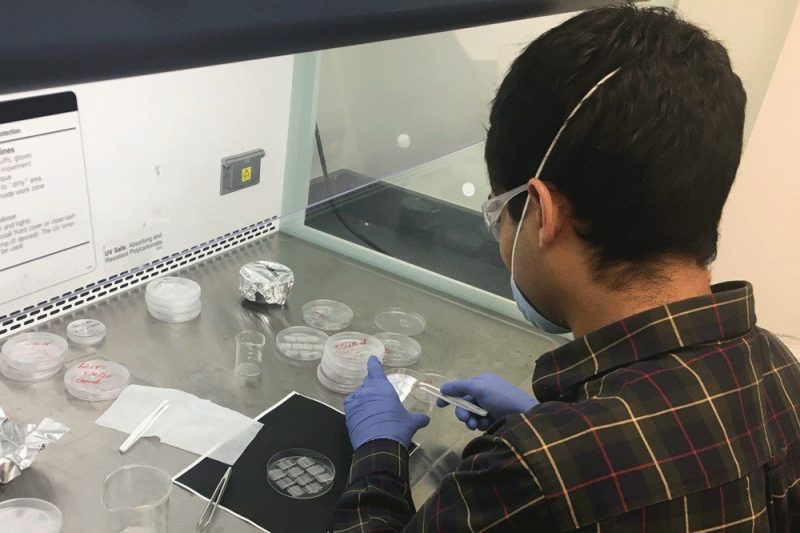

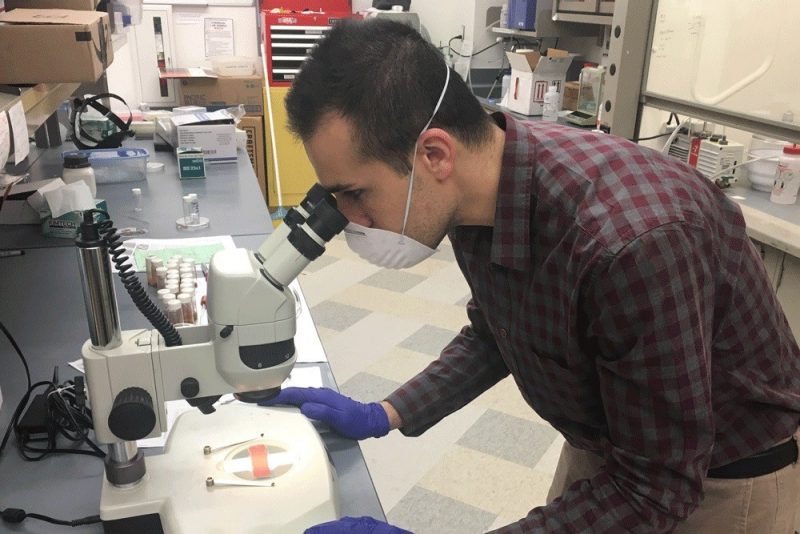

William Ducker, professor of chemical engineering at Virginia Tech, and his research group are developing a coating that inactivates the virus, SARS-CoV-2, in a short period of time. The virus is currently known to be detectable for up to a week. The team aims to make a coating that will leave the virus inactive in an hour or less. Clearly the shorter the time, the better the result. The coating could be put on many communal objects like door handles and shopping carts. It is made from polymers and particles that are deposited in a film on the object. Ducker and chemical engineering Ph.D. students, Saeed Behzadinasab and Mohsen Hosseini, have been working to design and manufacture samples. The films are being tested for their ability to inactivate the SARS-CoV-2 virus in the laboratory of Professor Leo Poon in the laboratory of Professor Leo Poon, School of Medicine, University of Hong Kong.

Chang Lu, the Fred W. Bull Professor of Chemical Engineering, and Rong Tong, Assistant Professor of Chemical Engineering, are working to develop a microfluidic platform for rapid and precise measurement of COVID-19 antibodies. The goal is to develop a quick, precise and low-cost antibody test that will be useful for serology surveillance and vaccine development. Antibodies are proteins that help fight off infections and usually provide protection against re-infection. Many current antibody testing of COVID-19 are not highly-specific or sensitive.

Padma Rajagopalan, the Robert E. Hord, Jr. Professor of Chemical Engineering, is working with a team of researchers to repurpose existing drugs for COVID-19. Since a virus must necessarily co-opt host cellular processes in order to replicate, a promising approach is to develop or repurpose drugs that target human proteins required by the virus. The multi-institution team is developing a computational, network-based, drug repositioning strategy to prioritize existing, approved drugs as anti-COVID-19 agents. Even in the early stages of this research, the team has independently identified several drugs that are in clinical trials for COVID-19.

Read more about the efforts at Virginia Tech here.