UO Lab at Virginia Tech

Note: You MUST Course Request Summer 2022 (Course request opens on March 15th).

CHE 4014: Chemical Engineering Laboratory

Offered on-campus at Virginia Tech during the summer. The 5 credit course is taken during either Summer I or Summer II and takes 6 weeks to complete.

Summer 2022 Dates:

Summer I: May 23rd-July 1st

Summer II: July 6th-August 12th

Note: Students are NOT guaranteed their first choice of enrollment in Summer I or Summer II. Student enrollments must be balanced between the two sessions because of space limitations in the laboratory. If you do not get into your preferred section during course request, you may request a force-add with a valid reason (usually an offer letter for a coop/internship or something similar) but you are not guaranteed entry.

Lab Format:

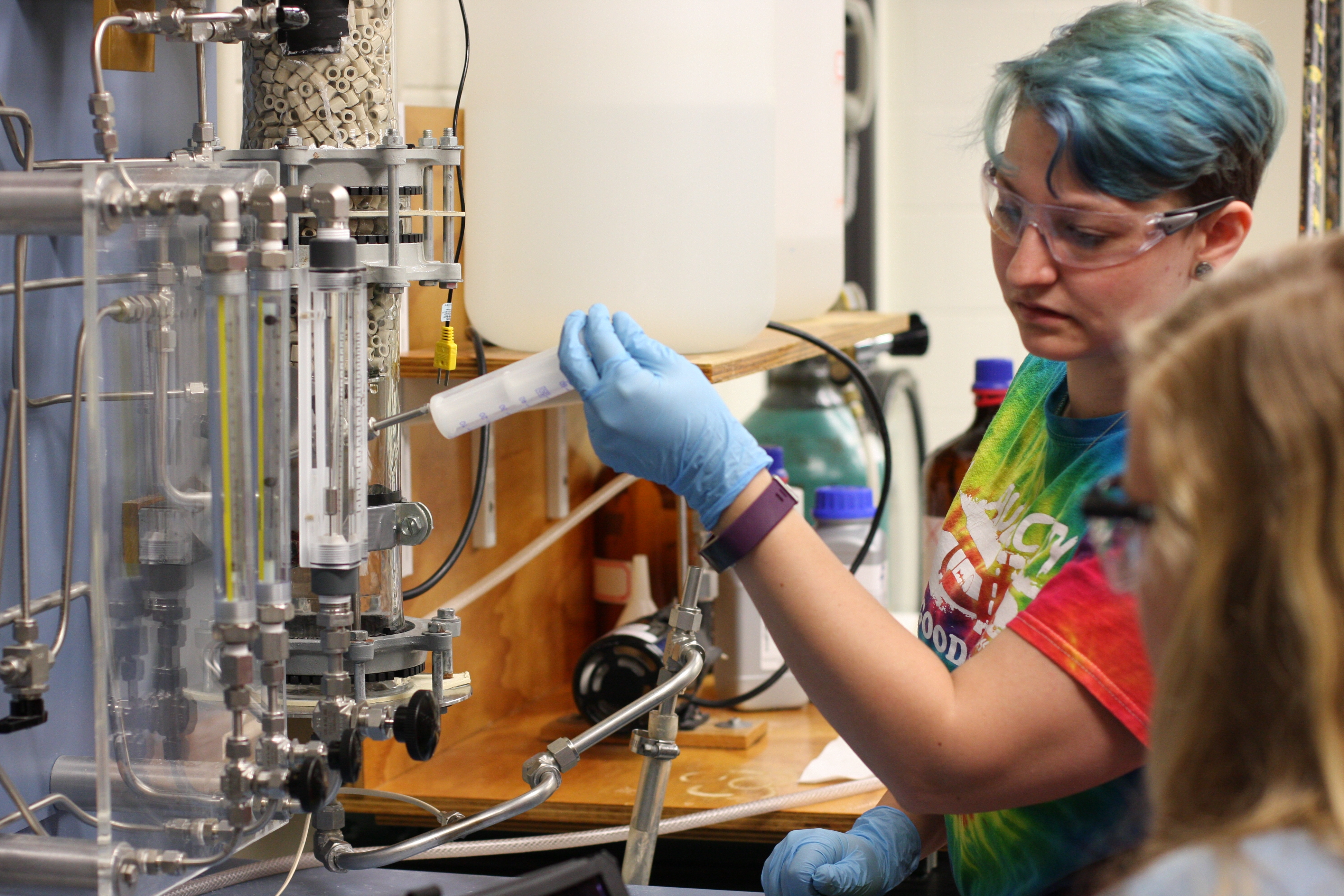

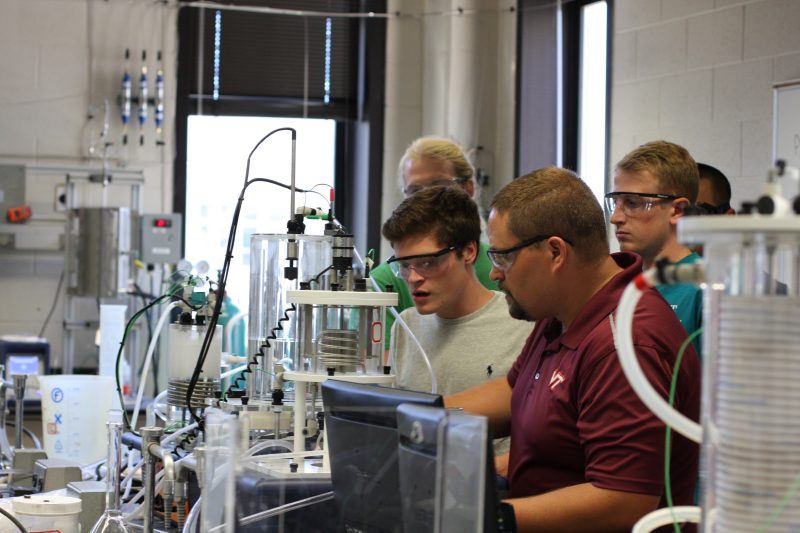

Students work in groups of 3-4 students and complete 8 laboratory experiments. Additional assignments may be added by the instructor. Each experiment is assigned 3 working days, and there are no breaks between experiments. As a result, students are often asked to multitask – completing the report for the prior experiment and preparing for the next experiment while performing labwork for the current experiment. Associated with each experiment is 1) a preliminary report and research plan prepared prior to the labwork, and 2) a written and/or oral report analyzing and discussing the results of the work. The final experiment concludes with a formal poster session in the Goodwin Hall Atrium.

Significant emphasis is placed on safety, experimental design, data analysis, oral and written communication, and the ability to work in groups.

Locations:

The UO Lab is located in Hancock Hall (rooms 109, 210, and 211). Lectures, meetings, and oral presentations take place in Hancock 209. Students are also given access to classrooms in Randolph Hall to use as group offices and workspaces.

Instructors:

The labs are overseen by a CHE faculty member and supported by a number of graduate teaching assistants.

Experiments:

- Batch Distillation: Large glass bubble cap tray distillation column used to study the separation of mixtures based on differences in volatility. The column is equipped with computer control and data acquisition. Sample ports can be used to examine the composition in trays throughout the column. Analysis of samples by refractive index or gas chromatography.

- Continuous Distillation: Small (8 tray) sieve tray column or packed bed column used to study the separation of mixtures based on differences in volatility. The column can be operated in batch or continuous mode and at ambient or reduced pressures. Analysis of samples by refractive index or gas chromatography.

- Liquid/Liquid Extraction: Continous stirred tank liquid/liquid contactor for studying mass transport between liquid phases as a function of composition, mixing intensity, and flow rates. Analysis of samples by UV-VIS spectrophotometry.

- Stripping: Small glass sieve tray column used to study the stability of operation as a function of gas and liquid flow rates, and the stripping of a volatile component from a liquid stream as a function of composition and operating conditions.

- CO2 Absorption: Packed bed column used to study operating regimes (gas/liquid holdup, pressure drop, residence time) and effectiveness of CO2 absorption from air as a function of gas and liquid flow rates. Equipped with computer data acquisition and PID control.

- Membrane Separation: Apparatus for the separation of Nitrogen and Oxygen from an air stream consisting of two hollow fiber membrane units that can be run in series or parallel. Transport behavior is studied as a function of flow rates and pressures.

- Filtration: Rotary Drum filter and leaf filter apparatus used to separate a solid powder from a liquid suspension. Variables include submersion time, rotation speed, suspension composition, and filter cloth type.

- Reaction Engineering (CSTR): 1 liter jacketed stirred tank reactor equipped with variable flow pumps for the reagents and a circulating water bath for temperature control. Computer data acquisition is by flow through UV-VIS spectrophotometry.

- Reaction Engineering (TFR): Tubular flow reactor equipped with computer data acquisition and control. Analysis is by conductivity.

- Fermentation: Batch fermentation experiment to study the growth of yeast as a function of aerobic or anaerobic conditions and temperature. Analysis is by turbidity measurement, specific gravity measurement, and refractive index (BRIX) measurement.

- Polymer Extrusion: Single screw extruder used to study the non-Newtonian flow and processing of a polymer as a function of temperature, screw speed and die diameter.

- Fluidization: Fluidized bed used to study the fluidization behavior of particulate materials as a function of density, particle size, particle shape, and bed height. Primary analysis using pressure drop measurements.

- Fuel Cells: Proton exchange membrane fuel cell test stand used to study the performance of a polymeric PEM fuel cell stack as a function of pressure, humidity, temperature and hydrogen and air flow rates.

- Heat Exchange: Shell and tube (steam/water) and concentric pipe (water/water) heat exchangers with computer control and data acquisition used to study the effectiveness of heat transfer as a function of relative temperatures and flow rates. Also used to study control performance.

- Bubble Column: Gas/liquid contactor consisting of a large glass liquid-filled column through which air is bubbled. Hold-up in the column is studied as a function of fill height, gas flow rate, and composition of surface active additives to the liquid phase.

- Process Control: A process control experiment that allows exploration of control parameters in P, PI, and PID control schemes for flow control, level control, temperature control, and mixing applications.

- Polymerization: Multi-reactor apparatus for the polymerization of styrene via emulsion polymerization. The effect of process parameters (i.e. temperature, reaction time, reagent concentrations) on final product properties (molecular weight) is examined.

- Biofuels: Reactor apparatus for the the base catalyzed transesterification of vegetable oil (fresh or waste oil) to produce biodiesel.